| POTTERY FORMING |

|

|

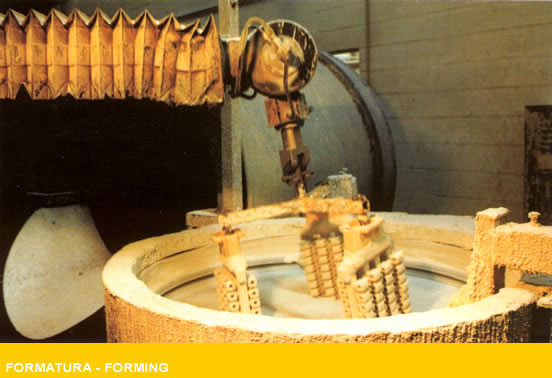

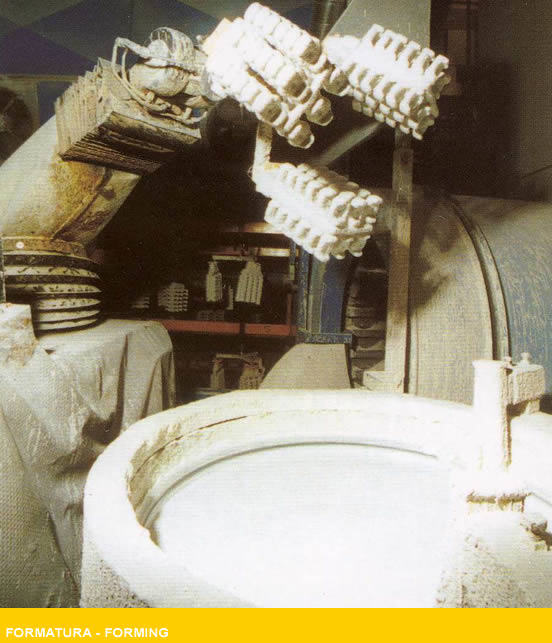

The operations being carried out in this room are utterly important for a successful standard of the whole production process.

HereSTANDARD FORMS are dipped into the various thanks containing refractory binders (picture 5) and eventually brought to rotary vertical

spray booths, where the refractory grit falls down and lays, adhering to the surface of

STANDARD FORMS (fig. 2).

(picture 6).

These operations, namely the dipping and adhesion of refractory grit, are repeated 6-7 times, with due intervals, by a computerized robot-operated device.

Thus STANDARD FORMS are coated with a solid pottery shell.

|